The 1 ton jumbo bags are increasingly popular in various industries. According to recent market research, the demand for bulk bags has risen by 30% in the past five years. These bags are designed to hold significant weight, making them ideal for transporting materials like sand, grains, and fertilizers. They provide a reliable solution for storage and shipping needs.

In construction and agriculture, 1 ton jumbo bags serve a vital role. They minimize wastage and are cost-effective for large businesses. However, companies sometimes face challenges regarding their reuse and recycling. While they offer convenience, the environmental impact of single-use bags is a growing concern.

Understanding the balance between utility and sustainability is essential. It prompts industries to consider innovative technologies for recycling these bags. As more companies prioritize eco-friendly practices, the future of 1 ton jumbo bags may evolve. There’s a clear need to reflect on how we use these bags responsibly while still meeting economic demands.

A 1 ton jumbo bag is a large container made from woven polypropylene. This type of bag is designed to carry heavy loads, typically weighing up to 1 ton. They are often used in industries like construction, agriculture, and recycling. The size and structure of these bags allow for efficient handling and transport of bulk materials.

These bags have a simple design, often featuring an open top and a bottom discharge, making filling and emptying straightforward. However, mistakes can happen. Sometimes, bags may not be properly sealed, leading to material spillage. This can waste resources and create safety hazards.

The versatility of 1 ton jumbo bags is notable. They can hold anything from sand and gravel to grains and scrapped materials. Yet, their durability comes with a caveat. If exposed to harsh weather conditions, they can deteriorate quickly. So, proper storage is essential. Awareness of these factors is crucial for effective use in various applications.

Jumbo bags, often called bulk bags, are versatile containers used in various industries. They are commonly made from woven polypropylene, a durable plastic material. This construction provides strength and flexibility. The bags can carry heavy loads, typically up to one ton. Their sturdy design makes them suitable for storing and transporting materials like sand, gravel, and agricultural products.

The manufacturing process of jumbo bags involves several steps. First, high-quality polypropylene is selected. The material is then woven into a fabric that is both strong and lightweight. Some bags are coated for added water resistance. However, not all bags are created equal. Some may suffer from weak seams or poor stitching, which could lead to failures during use. It's essential to recognize this issue when choosing a jumbo bag for specific applications.

In addition to polypropylene, jute and cotton are also used for eco-friendly alternatives. These materials offer biodegradability but may not match the durability of synthetic options. Considering the intended use is crucial. For example, jute bags might not be the best choice for wet environments. Reflecting on the material choice can help in making better decisions for cost-effective and sustainable practices.

A 1 ton jumbo bag, also known as a FIBC (Flexible Intermediate Bulk Container), serves multiple industries. These bags can carry various materials ranging from grains to construction materials. In construction, they often hold sand, cement, or soil, making bulk transportation easier. A report by Smithers Pira highlights that the demand for jumbo bags is growing at approximately 5% annually, particularly in emerging markets.

In agriculture, these bags are commonly used for storing grains. This minimizes storage space and protects products from pests and moisture. According to a recent industry analysis, about 80% of agricultural suppliers now consider using jumbo bags for enhanced efficiency. Their capacity can prevent spoilage, a crucial factor in maintaining grain quality.

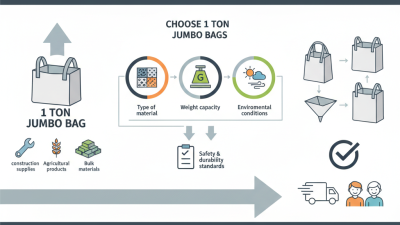

Tips: When using jumbo bags, choose the right fabric and size for your needs. Ensure the bags are well-sealed to avoid contamination. Also, consider the weight load, as overloading can lead to failures. While jumbo bags are convenient, proper storage and handling are vital. Inadequate management could lead to tear or loss of materials.

| Application | Description | Industry | Material Used |

|---|---|---|---|

| Construction | Used for transporting sand, gravel, and other construction materials. | Construction | Sand, Gravel |

| Agriculture | Ideal for storing and transporting grains, fertilizers, and seeds. | Agriculture | Grains, Fertilizers |

| Mining | Used for handling bulk materials like ores and minerals. | Mining | Ores, Minerals |

| Food Industry | Suitable for storing and transporting bulk food products. | Food | Food Grains, Sugar |

| Chemicals | Commonly used for chemical powders and granules. | Chemical | Chemical Powders |

1 Ton Jumbo Bags are essential in various industries, providing efficient storage and transportation solutions. Their size allows for a significant volume of materials to be handled easily. According to industry reports, these bags can hold approximately 1,000 kilograms of dry bulk materials. This capacity makes them popular in construction, agriculture, and mining sectors.

Using 1 Ton Jumbo Bags offers numerous benefits. They are highly durable, made from woven fabric, which helps protect the contents from moisture and contamination. Their lightweight nature facilitates easy handling, reducing labor costs. Additionally, they can be reused multiple times, promoting sustainability. A study indicates that using these bags can lower packaging waste by up to 25%.

Tips: Ensure you inspect the bags for any signs of wear before use. Not all bags are suitable for every type of material; select a bag that fits your specific needs. Keeping your storage area organized will improve efficiency when using these bags.

Jumbo bags are typically used for storing bulk materials. These bags hold a capacity of approximately one ton. Their size makes them ideal for handling large quantities of products. However, proper storage and handling are crucial to ensure safety and efficiency.

When storing jumbo bags, place them on a flat surface. This prevents them from tipping over. Avoid stacking bags too high as it may cause structural failure. Each bag should be secured tightly if stored outdoors to protect against weather damage. Inspect them regularly for any signs of wear or damage. Handling should also be done with care. Use appropriate machinery for lifting. Unsafe lifting practices can lead to injuries or bag rupture.

Transporting jumbo bags requires attention. Ensure they are loaded securely onto trucks. During transit, avoid sharp objects that could puncture the bags. Uneven loads can shift and cause accidents. It’s easy to overlook but vital to check weights as overloading can lead to failures. Proper training for staff handling these bags can reduce risks. Simple guidelines can make a big difference in safety and efficiency.

This bar chart represents the various uses of 1 Ton Jumbo Bags across different industries. The data shows that Agriculture and Construction are the leading sectors utilizing these bags, followed by the Chemical Industry, Waste Management, and Food Industry. Each bar indicates the number of uses measured in thousands, highlighting the versatility of jumbo bags in diverse applications.

Copyright 2025 © Custom Packaging Products | All Rights Reserved