Manufacturer of plastic bags requires a three-step process: extrusion, printing, and bag making. Depending on the type of bags being made, the plastic industry will alter the steps mentioned above.

Plastics manufacturers specialize in certain types of plastic material, as it would be cost prohibitive to have many different types of precision plastic machining to make all plastic products.

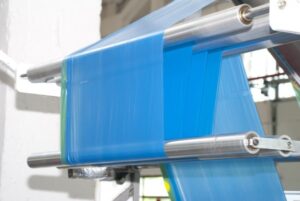

Extrusion of Plastic

Extrusion is the process of squeezing molten plastic through a die to form a continuous sheet or shape. All plastics are derived from fossil fuels and begin as what is called plastic resin. The plastic material or resin is melted at high temperatures and forced through an extruder.

During this step, various additives can be added to the molten plastic to make it stronger, more flexible and resistant to moisture. The melted plastic can either be blown into a sheet or into small filaments used in woven poly bags.

Printing Plastic Bags

Next, the material is then fed into a printer where various designs are printed onto the plastic – such as logos, branding, advertising and product information. Once printing is complete, the plastic is cut into bag shapes and sealed with ultrasonic welding.

Popular types of materials used for extrusion include low density polyethylene (LDPE), polypropylene (PP) and plastic sheeting.

Making Plastic Bags

After the printing takes place, the plastic sheets are formed into bags, plastic tubes or other plastic products by either sealing the ends at the correct sizes or leaving the material as sheets. If the bags need to have color vs. clear bags, then a color additive would have been mixed into the resin before the extrusion takes place.

If the manufacture is making a woven poly bag such as bulk bags or sand bags, then the filament extruded will be woven via loom into actual plastic fabric. That fabric will then be used to make bulk bags or super sacks.

Additives Used In Plastics

During the plastic extrusions process, various additives can be added to the molten plastic to alter its properties. These additives can increase flexibility, strength, durability, and resistance to heat, UV inhibitor, and moisture. Additives commonly used in extrusion include lubricants, stabilizers, antioxidants, plasticizers, fillers, colorants and other specialty materials.

Plastic Manufacturers

Plastic manufacturers are companies that specialize in the production of plastic products, such as poly bags, bulk bags, poly packaging, containers, and other items. The manufacturing begins with the raw plastic materials or plastic resins to melt for processing.

Then, either plastic injection molding, blow molding, or extrusion is used to make the desired plastic material. Also, the product being created will either be a rigid plastic or a flexible poly packaging.

The cost of plastic is dictated by the global plastics market and is a commodity item. Pricing in the plastics industry is always fluctuating on a daily basis due to plastic materials being traded globally.

Plastic manufacturers are either buying plastic materials in then spot market or through a fixed contract. Top plastic manufacturing companies always must be cognizant of the market pricing and inventory of their resin.

Popular Plastics

- High density polyethylene (HDPE) Used mostly for rigid plastic containers such as shampoo bottles with blow molding; also plastic injection molding is used for harder plastics

- Low density polyethylene (LDPE) Used mostly for plastic film

- Polypropylene (PP) Used for both containers and bulk bags

- Polyvinyl Chloride (PVC) used for film, containers

- Polyethylene Terephthalate (PET) Used mostly for water bottles

Melting Point of Plastics

The melting point of most plastics used to make bags is typically around 120-150°C (248-302°F). At this temperature, the molten plastic can be easily formed into sheet or bags. Depending on the type of plastic being used, additives can also be added to modify the characteristics and performance.

Some common additives include antistatic agents, lubricants, colorings, optical brighteners and stabilizers.

Once all steps are completed, the plastic bags are ready for use. From controlling humidity to promoting products and services, plastic bags are among the most versatile and useful packaging materials available.

Industrial plastic bags

Industrial bags are different than retail bags, as they will need to be stronger to handle the demands of shipping industrial products. Retail bags may be for a shopper which does not need to carry much weight. In contrast, industrial bags or bulk bags may have to safely carry 4,000 lbs of product across the world. These bags will be much heavier wether it’s an extruded bag or a woven polypropylene bag.

On a final note, it’s important to remember that plastic bags can be hazardous when manufactured or used incorrectly. To avoid any potential issues, make sure you follow all relevant regulations and safety guidelines when manufacturing plastic bags.

This will ensure the quality of your product and help protect the environment.

By understanding the manufacturing process of plastic bags and its various components, you can easily create high-quality products that meet customer demands.