Choosing the right packaging solution is critical for a variety of industries, and one of the most versatile options available in the market today is the 1 ton jumbo bag. These large bags have gained immense popularity due to their ability to efficiently store and transport bulk materials ranging from construction supplies to agricultural products. Understanding how to select the appropriate 1 ton jumbo bags for your specific packaging needs can greatly enhance your operational efficiency and reduce costs.

When it comes to selecting 1 ton jumbo bags, various factors must be taken into consideration, including the type of material to be stored, the weight capacity required, and the environmental conditions the bags will face. Properly assessing these factors ensures that the bags not only meet the storage requirements but also comply with safety and durability standards. Additionally, evaluating the various styles and configurations of 1 ton jumbo bags available in the market can help businesses tailor their choice to suit their unique shipment and storage demands. By making informed decisions, companies can leverage the advantages of 1 ton jumbo bags, maximizing both the reliability of their packaging and the satisfaction of their customers.

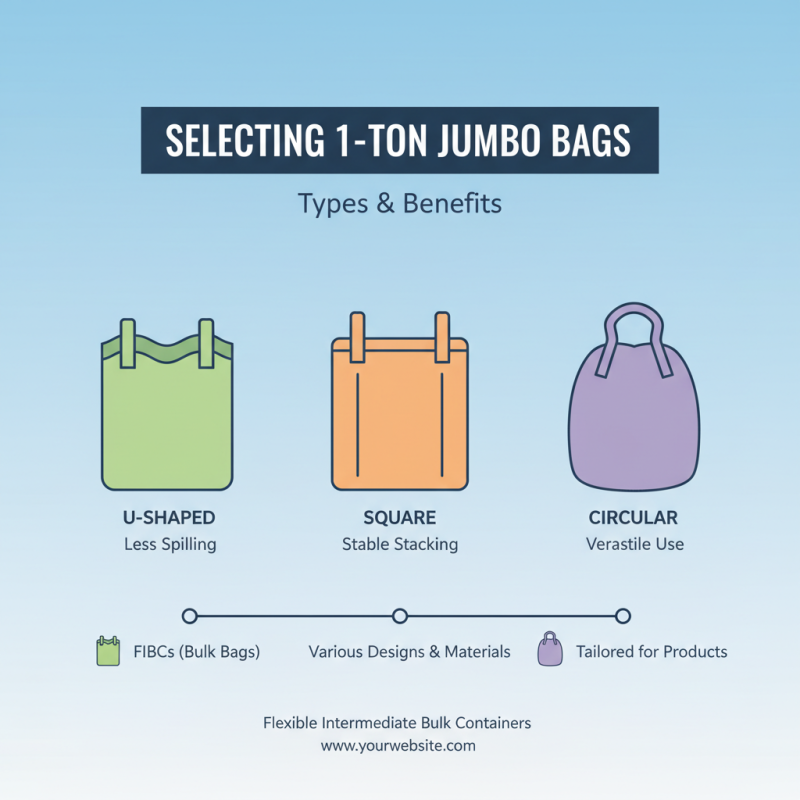

When it comes to selecting the right 1 ton jumbo bags for your packaging needs, it's important to understand the different types available in the market. Jumbo bags, also known as bulk bags or FIBCs (Flexible Intermediate Bulk Containers), come in various designs and materials tailored for specific applications. Common types include U-shaped, square, and circular bags, each of which offers unique advantages based on the product being stored or transported. For example, U-shaped bags are less susceptible to spilling, while square bags provide a more stable stacking option.

Additionally, understanding the materials used in jumbo bags can greatly impact your choice. Most are made from woven polypropylene, which is durable and resistant to UV rays, moisture, and chemicals. You can also find bags with liners for added protection against moisture, or those specifically designed for heavyweight loads. Evaluating your product’s characteristics, such as its size and weight, will help narrow down your options.

**Tips:** Always consider the bag's weight capacity and safety factor to ensure it can handle your specific needs. Furthermore, reviewing the bag's construction quality can help prevent issues related to ruptures or leaks during handling. Lastly, don't forget to check for any necessary certifications, especially if you are dealing with food-grade or hazardous materials.

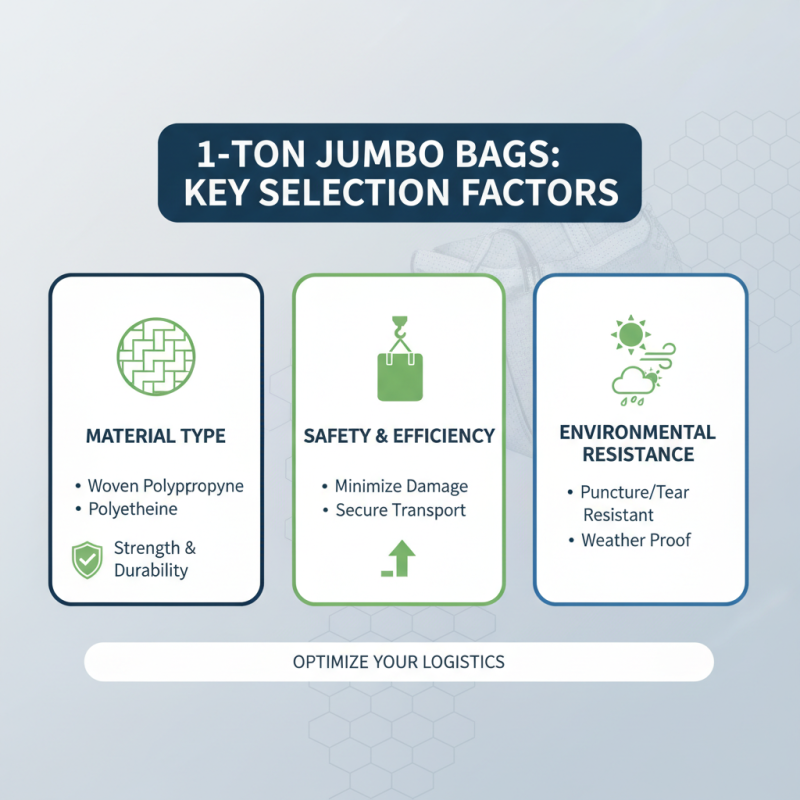

When selecting 1-ton jumbo bags for your packaging needs, it is essential to consider several key factors that will ensure safety and efficiency in your logistics. Firstly, material type plays a crucial role in determining the bag's strength and durability. Common materials include woven polypropylene and polyethylene, each offering different levels of resistance to punctures, tears, and environmental conditions. Choose a material that aligns with the nature of your products and their storage conditions to avoid potential damage during transport or storage.

Another important factor to evaluate is the bag's design and configuration. Jumbo bags come in various designs, such as U-panel, square, and tubular. The choice of design should be influenced by how the bags will be used and stacked. Additionally, consider the bag's lift capability, as different designs can handle varying weights and forms of products. Proper design not only improves stability during transport but also maximizes storage space. Finally, ensure that the bags meet any necessary industry standards and specifications, as this can influence safety and regulatory compliance.

When selecting 1 ton jumbo bags, it is essential to consider the industry standards and regulations that govern their use. The International Organization for Standardization (ISO) provides guidelines that ensure jumbo bags meet specific quality and safety parameters. For instance, ISO 21898 outlines the specifications for flexible intermediate bulk containers (FIBCs), including load capacity, filling methods, and handling procedures. Adhering to these standards ensures the bags can withstand the stresses of transportation and storage while maintaining the integrity of their contents.

In addition to ISO standards, industry-specific regulations may apply depending on the materials being packaged. For example, the Food and Drug Administration (FDA) sets stringent guidelines for materials that come into contact with food products, ensuring they are food-safe and free from harmful chemicals. According to a recent report by the Flexible Packaging Association, compliance with regulatory frameworks not only protects consumer health but also enhances brand reputation and market acceptance. With the global market for jumbo bags projected to reach 7.1 billion USD by 2027, manufacturers that prioritize compliance with industry standards position themselves favorably in an increasingly competitive landscape.

When budgeting for 1 ton jumbo bags in your packaging strategy, it's essential to consider several factors that impact overall costs. The price of these bags can vary widely based on material type, design complexity, and the manufacturer. Generally, bags made from higher-grade materials will offer better durability and strength but may also come with a higher price tag. Businesses should analyze the specific needs of their products to choose the right materials without overspending, ensuring a balance between cost-effectiveness and required quality.

Additionally, order volume plays a critical role in determining the budget. Bulk purchasing often leads to significant discounts, so companies should evaluate their packaging needs over time and place larger orders when feasible. It’s also prudent to assess shipping costs and lead times when selecting suppliers, as these factors can dramatically affect the overall expense. Establishing a clear understanding of your packaging requirements and how they align with your budget can facilitate more informed decisions, ultimately optimizing your packaging strategy while keeping costs under control.

| Bag Type | Material | Load Capacity (kg) | Dimensions (cm) | Price per Bag ($) | Estimated Lifespan (cycles) |

|---|---|---|---|---|---|

| Standard FIBC | PP Woven | 1000 | 90 x 90 x 110 | 10 | 5 |

| Conductive Bag | Conductive PP | 1000 | 90 x 90 x 110 | 15 | 3 |

| Ventilated Bag | PP Woven with Ventilation | 800 | 90 x 90 x 110 | 12 | 4 |

| Liner Bag | PP Woven with Liner | 1000 | 90 x 90 x 110 | 20 | 6 |

| Heavy Duty Bag | PP Woven Reinforced | 1200 | 90 x 90 x 110 | 25 | 5 |

Sustainability has become a crucial factor in the production and selection of 1-ton jumbo bags, particularly as industries shift towards more environmentally friendly practices. According to a recent report by Smithers Pira, the global market for sustainable packaging is expected to reach $500 billion by 2025, driven by increased consumer demand for eco-friendly products. In the realm of jumbo bags, materials such as recycled polypropylene are gaining traction, with manufacturers reporting that over 30% of new bags produced in 2023 incorporate recyclable content. This trend not only reduces the carbon footprint of the bags but also ensures that packaging aligns with the growing consumer preference for sustainable solutions.

When selecting the right jumbo bags, buyers should consider not only the material but also the manufacturing processes involved. Certifications such as ISO 14001 (environmental management) and the use of water-based inks or biodegradable additives are indicators of a company’s commitment to sustainability. A study conducted by the Flexible Packaging Association found that companies adopting sustainable practices report a 20% increase in customer loyalty. Furthermore, durability and reusability are key criteria; opting for bags that are designed for multiple uses can significantly decrease waste.

As the industry evolves, understanding these sustainability trends will be essential for businesses looking to make informed decisions that meet both their packaging needs and environmental responsibilities.

Copyright 2025 © Custom Packaging Products | All Rights Reserved