In today's fast-paced industrial landscape, choosing the right flexible intermediate bulk container (FIBC bags) is crucial for optimizing operational efficiency. According to a recent report by Smithers Pira, the global FIBC market is projected to grow by 5.6% annually, fueled by the increasing demand across various sectors such as agriculture, construction, and food processing. This growth underscores the importance of selecting FIBC bags that not only meet specific requirements but also align with sustainability practices, ensuring both performance and compliance.

Industry expert Dr. Michael Thompson, a leading figure in packaging solutions, emphasizes that "selecting the right FIBC bags can significantly impact supply chain dynamics and cost management." With a variety of options available, including different shapes, sizes, and materials, businesses must carefully assess their unique needs against the characteristics of each bag. Factors such as load capacity, handling, and environmental considerations should guide this decision-making process, as improper selection can lead to increased waste and inefficiencies.

As the market evolves, understanding the fundamental aspects of FIBC bags becomes paramount. An informed choice can not only enhance product safety and transport efficiency but also contribute to a company's overall sustainability goals. Therefore, a strategic approach to selecting the right FIBC bags is essential for any business looking to thrive in today's competitive environment.

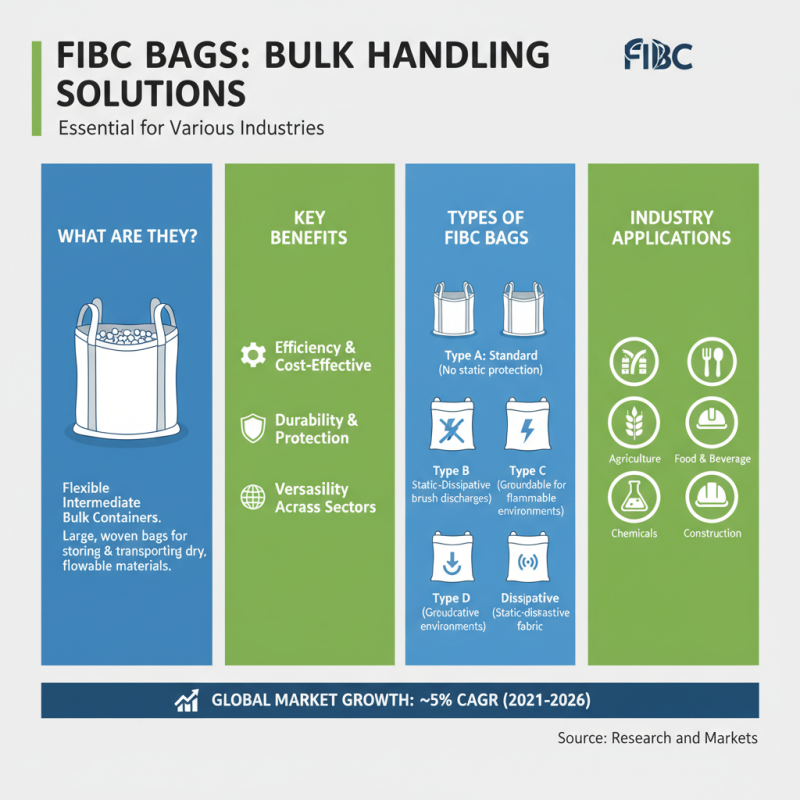

FIBC (Flexible Intermediate Bulk Containers) bags are essential for various industries due to their versatility and efficiency in bulk material handling. Understanding the different types of FIBC bags available in the market can significantly impact operational efficiency and cost-effectiveness for businesses. According to a recent market report by Research and Markets, the global FIBC market is expected to grow at a CAGR of around 5% from 2021 to 2026, highlighting the rising demand for these bags across sectors such as agriculture, food, chemicals, and construction.

There are several types of FIBC bags tailored for specific use cases. Type A bags, made from conventional woven polypropylene, are suitable for non-flammable materials. In contrast, Type B bags are designed to minimize the propagation of fire but are not conductive. For hazardous materials, Type C bags equipped with conductive threads are necessary to prevent static electricity buildup. Finally, Type D bags are antistatic, providing protection in hazardous environments. A study by Smithers Pira indicates that the food and pharmaceutical industries increasingly prefer Type D bags, with market adoption growing by over 15% annually due to their safety features.

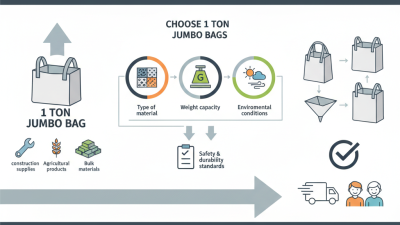

When choosing the right FIBC bag, it’s critical to consider the material properties, intended use, and environmental conditions. Businesses must evaluate factors such as the type of product being stored, moisture levels, and any regulatory requirements specific to their industry. By comprehensively understanding these factors, companies can select the appropriate FIBC solution that not only meets their operational needs but also aligns with safety and regulatory standards.

When it comes to selecting the right FIBC (Flexible Intermediate Bulk Container) bags for your business, there are several key factors to consider that can significantly impact your operational efficiency and product safety. The material used in FIBC production is crucial; most bags are made from woven polypropylene, which offers strength and flexibility. According to industry reports, the global FIBC market is projected to grow at a CAGR of 5.2% from 2021 to 2026, indicating increasing demand for these versatile containers across various industries including agriculture, chemicals, and construction.

Another critical consideration is the bag's capacity and dimensions, as selecting the appropriate size can prevent wastage and enhance storage efficiency. Industry standards suggest that businesses should carefully assess their specific product weights and volumes to determine the best fit. For instance, FIBC bags typically range from 500 to 2000 kg in capacity. Choosing the right type also involves understanding the intended use; some bags are designed for single use, while others can be reused multiple times.

Tips: Always check for certifications that indicate compliance with industry standards, such as those set by the International Organization for Standardization (ISO). It's essential to ensure that the bags are suitable for the type of materials you'll be transporting, as improper bag selection can lead to safety hazards or product contamination. Additionally, consider the environmental impact and look for manufacturers that offer recyclable or biodegradable options.

When selecting FIBC (Flexible Intermediate Bulk Container) bags, understanding load capacity and strength requirements is paramount for ensuring the safety and efficiency of your operations. The International Standards for FIBCs specify various load ratings that can range from 500 kg to 2,000 kg, depending on the bag design and intended use. For instance, according to a report by the FIBCA (Flexible Intermediate Bulk Container Association), the proper selection of bag type based on load capacity not only contributes to operational efficiency but also minimizes the risk of failure and potential liability.

Strength requirements are equally crucial, as they dictate how well the FIBC can withstand various conditions during transportation and storage. Data indicates that using bags with insufficient strength can lead to product loss and damage, costing businesses substantially. A study conducted by industry experts highlighted that nearly 30% of FIBC failures during handling are linked to low tensile strength and inadequate seam integrity. Therefore, businesses should carefully assess both vertical and horizontal strength ratings, selecting bags constructed from high-quality materials and reinforced seams.

Ultimately, a thorough evaluation of load capacities and strength requirements, backed by data and industry standards, will empower businesses to make informed choices regarding FIBC bags that align with their specific operational needs. This assessment ensures not only the safety of the materials being transported but also enhances the overall cost-efficiency of supply chain practices.

When selecting the right FIBC (Flexible Intermediate Bulk Container) bags for your business, material compatibility between the bags and your product is crucial. Understanding the properties of both the FIBC materials and your products will help ensure the safety and integrity of your goods during storage and transport. Common materials for FIBC bags include woven polypropylene, which is strong and durable but may not be suitable for products sensitive to moisture or chemicals.

**Tips:** Always consider the chemical composition of your product. For instance, if you deal with corrosive substances, look for FIBCs made from ESD (Electrostatic Discharge) materials or those with special coatings that offer enhanced protection.

In addition, consider the operating environment. Extreme temperatures or outdoor conditions can impact the performance of the bags. If your product will be exposed to these conditions, ensure that the FIBC bags are designed to withstand such environments. The right choice will help prevent contamination, preserve product quality, and ultimately reduce costs associated with damage or loss.

**Tips:** Conduct a compatibility test with samples of your product and the FIBC material to verify their interaction before making a bulk order. This practice can prevent unforeseen issues down the line and ensure long-term satisfaction with your packaging solutions.

| Product Type | FIBC Material | Weight Capacity (kg) | UV Resistance | Application |

|---|---|---|---|---|

| Granular Chemicals | Polypropylene (PP) | 1000 | Yes | Chemical Industry |

| Food Products | Food-Grade Polypropylene | 1200 | No | Food Packaging |

| Construction Materials | Heavy-Duty Polypropylene | 1500 | Yes | Building Industry |

| Petrochemicals | UV Stabilized Polypropylene | 1300 | Yes | Chemical Storage |

| Recyclable Materials | Recyclable Polypropylene | 900 | No | Recycling Industry |

When selecting FIBC bags for your business, evaluating cost-effectiveness is crucial. Start by analyzing the total cost of ownership, which includes not only the purchase price of the bags but also potential shipping costs, durability, and any associated handling fees. Opting for bags that might appear cheaper at first glance may lead to higher replacement costs due to inferior quality or shorter lifespans. It's important to balance upfront costs with long-term savings by considering factors like reusability and recyclability, which can greatly impact the total expenditure over time.

Alongside cost, supplier reliability plays a significant role in the selection process. A trustworthy supplier should have a proven track record of timely deliveries and consistent quality. Investigating customer reviews and requesting samples can help gauge a supplier's reliability. Additionally, understanding their capacity to meet your business needs during peak seasons or unexpected surges in demand is essential. Establishing a strong partnership with a reliable supplier can lead to better terms, improved service, and ultimately contribute to the success of your operations.

Copyright 2025 © Custom Packaging Products | All Rights Reserved