When it comes to selecting the best PP FIBC bags for your business needs, understanding the complexities of these versatile containers is essential. As noted by industry expert John Smith, “Choosing the right PP FIBC bags can significantly enhance your operational efficiency and reduce costs.” With numerous options available in the market, businesses must carefully evaluate their requirements to ensure they select bags that not only meet their storage and transportation needs but also comply with industry standards.

PP FIBC bags, made from woven polypropylene, are known for their durability, strength, and recyclability. They are widely used across various industries, such as agriculture, construction, and chemical, making them a preferred choice for bulk packaging. However, the selection process can be daunting due to the myriad of factors that one must consider, such as bag size, weight capacity, and closure types. Understanding these parameters is crucial for optimizing logistics and ensuring product safety.

This guide aims to simplify the decision-making process while providing insights into the critical aspects of PP FIBC bags. By leveraging the expertise of professionals in the field and examining key factors, businesses can make informed choices that align with their operational goals and sustainability initiatives.

FIBC bags, commonly known as flexible intermediate bulk containers, are large bags designed for the efficient storage and transportation of bulk materials. These versatile bags can hold a wide variety of products, including grains, chemicals, and other granular items. Their flexible nature allows them to expand and fit the shape of the materials they contain, making them an ideal choice for businesses that require a cost-effective and space-saving packaging solution.

When choosing the right FIBC bags for your business needs, it's important to consider the specific applications you have in mind. Not all FIBC bags are created equal; they come in various designs and materials suited for different purposes. Whether you need a bag with a specific strength rating for heavy materials, or one that protects its contents from moisture or contaminants, understanding the application is crucial.

**Tips:** Always assess the weight and type of material you need to store when selecting FIBC bags. Additionally, consider whether you require bags with special features, such as UV protection or vented fabric, which can enhance performance based on your product's needs. Lastly, ensure you comply with industry standards and regulations related to your specific application, as this will not only safeguard your products but also streamline your operational processes.

When selecting the best polypropylene (PP) flexible intermediate bulk containers (FIBC) for your business, it's crucial to consider several key factors that ensure safety, durability, and efficiency. First, assess the type of material used in the construction of the bags. PP FIBC bags are available in various styles, such as circular or U-panel, and each design offers unique advantages in strength and flexibility. Choosing the right type according to your specific needs will help in protecting your products while maintaining the structural integrity of the bag.

Another essential factor to keep in mind is the intended use of the bags. Different applications may require specific features, such as UV resistance for outdoor storage or anti-static properties for the safe handling of flammable materials. Additionally, consider the weight capacity and dimensions required for your cargo. Evaluating these characteristics not only maximizes your storage efficiency but also minimizes the risk of damage during transportation. By focusing on these critical aspects, you can confidently choose PP FIBC bags that align with your operational requirements and enhance your business productivity.

When selecting PP FIBC bags for your business, understanding weight capacity and size requirements is paramount. Most polypropylene FIBCs are designed to hold between 500 kg and 3000 kg, depending on the construction quality and the intended application. According to the Flexible Intermediate Bulk Container Association (FIBCA), typical dimensions for FIBC bags range from 85 cm × 85 cm × 100 cm up to 120 cm × 120 cm × 220 cm, which provides ample options to suit specific storage and transport needs. It’s essential to assess not only the maximum weight the bag can handle but also the distribution of that weight during transport to ensure safety and efficiency.

Evaluating the size of the FIBC bag is equally crucial. The volume of the contents you plan to store will dictate the dimensions you require. A report by the International Bulk Container Association suggests that an optimal bag size not only accommodates the material but also facilitates easy stacking and minimizes transportation costs. Businesses need to consider the potential for product settling during transit, which can affect the effective capacity of the bag. Incorporating all these parameters into your selection process will help you choose the right PP FIBC bags that meet your operational needs while ensuring compliance with industry standards.

| Bag Type | Weight Capacity (kg) | Dimensions (cm) | Uses |

|---|---|---|---|

| Standard FIBC | 1000 | 90 x 90 x 110 | Grains, sand, powders |

| Conductive FIBC | 800 | 80 x 80 x 100 | Electronics, chemicals |

| Liner FIBC | 1200 | 100 x 100 x 120 | Food products, powders |

| Heavy Duty FIBC | 1500 | 110 x 110 x 130 | Construction materials |

| Turbulence-Proof FIBC | 1000 | 85 x 85 x 110 | Transporting liquids |

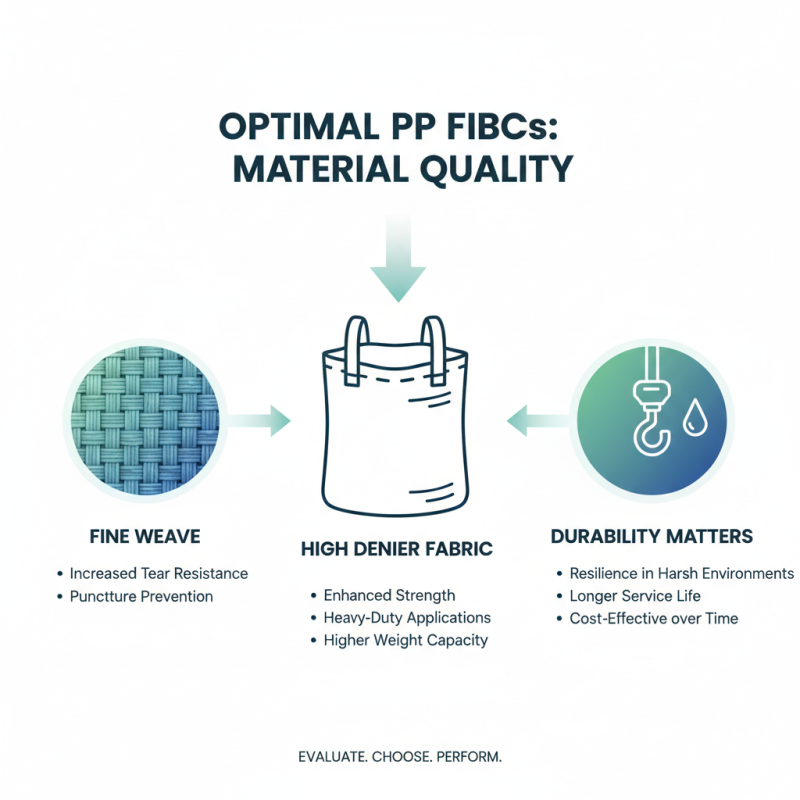

When selecting the best polypropylene (PP) flexible intermediate bulk containers (FIBC) for your business, evaluating material quality and durability is crucial. The material’s composition significantly impacts the bag's strength, weight capacity, and overall performance in various environments. High-quality PP fabric is typically marked by a fine weave, which enhances its resistance to tearing and puncturing. Additionally, consider the denier—higher denier fabrics offer better strength and durability, making them more suitable for heavy-duty applications.

Durability is not solely dependent on the fabric; factors such as UV resistance and weatherproofing also play vital roles. If your FIBC bags are to be stored outdoors or exposed to harsh conditions, opting for UV-stabilized materials can prevent degradation and extend their lifespan. Furthermore, the stitching and seams should be robust, as weak points in the design can lead to failure during handling or transportation. By thoroughly evaluating these aspects, businesses can ensure they are selecting FIBC bags that meet their specific needs, ultimately contributing to efficiency and cost savings in operational logistics.

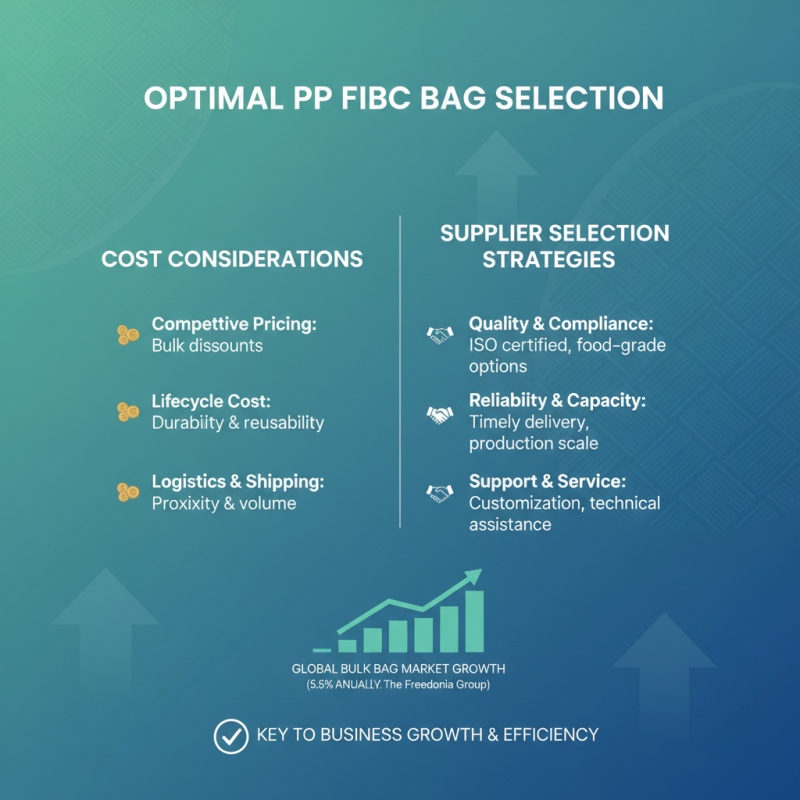

When selecting the best PP FIBC bags for your business, cost considerations and supplier selection strategies play a pivotal role. A report from The Freedonia Group indicates that the global market for bulk bags is expected to grow by 5.5% annually, reflecting increasing demand across various industries such as agriculture, chemicals, and construction. To align with this growth trajectory, businesses must identify suppliers who not only offer competitive pricing but also ensure quality and compliance with industry standards.

One of the critical factors to consider when choosing a supplier is their transparency regarding pricing structures. Reliable suppliers should be willing to provide detailed quotes and explain the cost components, which typically include material costs, production processes, and any additional fees for customization. Moreover, as highlighted by a study published in Packaging Strategies, sourcing from local suppliers can reduce transportation costs significantly—an essential consideration, especially in today’s volatile logistics environment. Establishing relationships with multiple suppliers can also help businesses negotiate better terms and foster competition, enhancing overall cost-effectiveness.

Additionally, companies must evaluate suppliers based on their production capabilities and lead times. A report by MarketsandMarkets emphasizes that manufacturers with advanced technology can produce bags faster and with less waste, resulting in lower costs per unit. Prioritizing suppliers who demonstrate an ability to meet fluctuating demand efficiently is crucial for maintaining a competitive edge. By carefully analyzing these cost considerations and employing strategic supplier selection, businesses can optimize their procurement processes and ensure they select the best PP FIBC bags tailored to their specific needs.

Copyright 2025 © Custom Packaging Products | All Rights Reserved