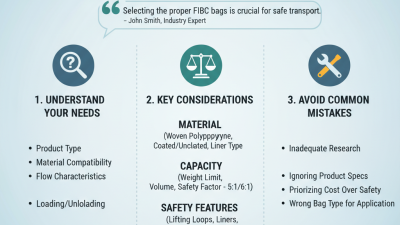

Using forklift bags effectively is crucial for maximizing their benefits in various industry applications. According to industry expert John Smith, "Proper handling of forklift bags can significantly improve operational efficiency." This statement underscores the importance of informed practices when utilizing forklift bags.

Many operators overlook the specifics of loading and securing forklift bags. Understanding weight distribution is key. An improperly loaded bag could lead to mishaps, wasting time and resources. Effective training on how to lift and maneuver these bags can prevent such issues.

Additionally, regular maintenance of forklift bags is often neglected. Inspecting for wear and tear ensures safety and longevity. An expert’s insights remind us that even minor flaws can escalate into serious problems. Reflecting on these factors encourages a culture of continuous improvement and safety awareness in operations involving forklift bags.

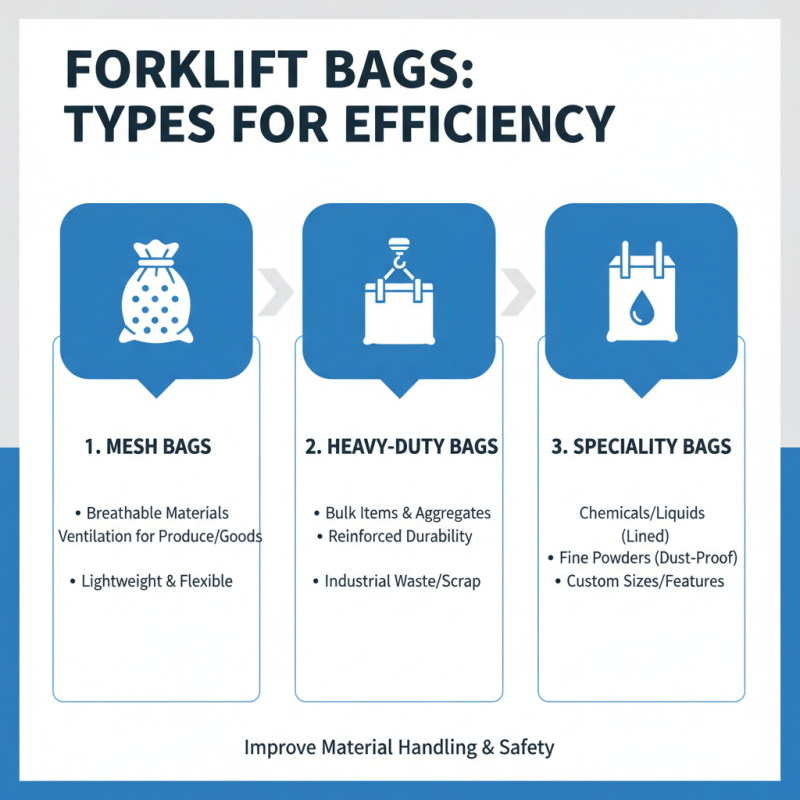

Forklift bags are vital in many industries. They come in various types, each designed for specific tasks. Understanding these types can improve efficiency. You may find mesh bags helpful for breathable materials. Heavy-duty options support bulk items, providing extra durability.

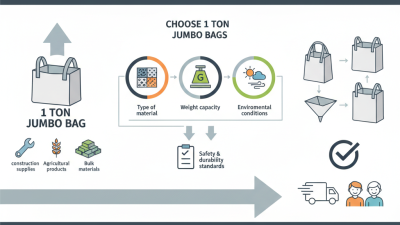

When using forklift bags, consider the load's weight and distribution. Overloading can lead to accidents. Ensure the bag is compatible with your forklift's capacity. This simple check can save time and reduce risks.

Another tip is to inspect the bags regularly. Some users overlook wear and tear. A small tear can escalate into a major issue. Be proactive in maintaining your bags to ensure they function effectively. Awareness of design features also improves effectiveness. For instance, reinforced handles enhance lifting safety. Understanding these details can make a significant difference in daily operations.

When selecting the right forklift bag, consider your specific needs. A recent industry report indicated that 35% of businesses reported inefficiencies due to incorrect bag choices. The weight capacity is one crucial factor. Bags can typically handle anywhere from 500 to over 2,000 pounds. Choosing the wrong weight limit can stall operations and increase risks.

Material type matters as well. Some bags are made from sturdy polypropylene, while others use woven fabrics. Polypropylene bags are generally more resistant to wear and tear. However, they may not be suitable for every environment. An estimated 25% of operators have faced issues with material breakdowns, highlighting the importance of proper selection.

Additionally, consider the bag's design and features. Some bags offer reinforced edges or loops for easier handling. A well-designed bag can significantly improve efficiency. If your operation switches between different tasks frequently, flexibility is key. Inadequate bags can lead to lost time and wasted resources, prompting a reevaluation of choices made. This reflection is vital for long-term operational success.

This chart illustrates the effectiveness of different types of forklift bags based on their usage scenarios. The data represents the percentage of users who found each type of forklift bag satisfactory in various settings.

When loading forklift bags, always ensure the weight is evenly distributed. This balance prevents tipping and promotes safe transport. If the load is uneven, it can cause issues during movement. Use a scale to verify the weight of each bag. Avoid guessing; precision is key.

Securing forklift bags correctly is crucial. Use straps or nets to hold bags in place. Check that they are tight but not overly so. Loose straps can lead to accidents. Ensure that the bags do not extend beyond the edge of the forklift. This reduces the risk of falling during operation.

Consider the surfaces where you'll be working. Uneven or slippery surfaces can pose hazards. Maintaining focus on the task is essential. Distractions can lead to mistakes. Reflect on past experiences—what went wrong? Learn from those situations to improve safety measures in future tasks.

When using forklift bags, safety should always be a priority. Proper training is essential for operators and staff. Mistakes can lead to accidents. For example, an untrained operator might overload a forklift bag, increasing the risk of tipping. Ensure everyone understands the weight limits. Check the bag's capacity before loading. This simple step can prevent serious injuries.

Always inspect forklift bags before use. Look for any wear or damage. If a bag shows signs of deterioration, do not use it. An unexpected failure can be catastrophic. Additionally, create a clear path for movement. Obstacles can cause accidents. Maintaining a clean work area is crucial.

Understanding your environment is also key. Lighting can affect visibility. Poor lighting can hide hazards. If you’re unsure about the area, conduct a risk assessment. Regularly remind staff of safety protocols. They need to know not to rush. A moment of caution can save a life. Always foster a culture of safety. A simple message about vigilance can make a difference.

When it comes to forklift bags, maintenance is key to extending their lifespan. Regular inspection is vital. Check for signs of wear and tear. Look for tears or punctures. Keeping bags clean prevents premature damage. Use a damp cloth to wipe off debris. Neglecting cleanliness can lead to larger issues over time.

Storage is also crucial. Store forklift bags in a cool, dry place. Avoid exposure to extreme temperatures or direct sunlight. These factors can weaken the material. Additionally, ensure that bags are not overloaded during use. Overloading can cause stresses that lead to failure.

Consider using protective covers for added security. This small investment can save money in the long run. Providing training for staff on proper bag handling is equally important. Misuse often leads to accidents and unnecessary repairs. Reflect on these aspects regularly to maintain efficiency.

| Tip | Description | Frequency | Importance Level |

|---|---|---|---|

| Regular Inspection | Check for any signs of wear, tear or damage before usage. | Before Each Use | High |

| Proper Loading Techniques | Ensure weight is evenly distributed in the bag. | Daily | High |

| Clean After Use | Remove debris and contaminants from the bag before storage. | After Each Use | Medium |

| Prevent Overloading | Do not exceed the weight limit specified for the bag. | Constantly | High |

| Store Properly | Keep bags in a dry and clean environment away from direct sunlight. | As Needed | Medium |

Copyright 2025 © Custom Packaging Products | All Rights Reserved