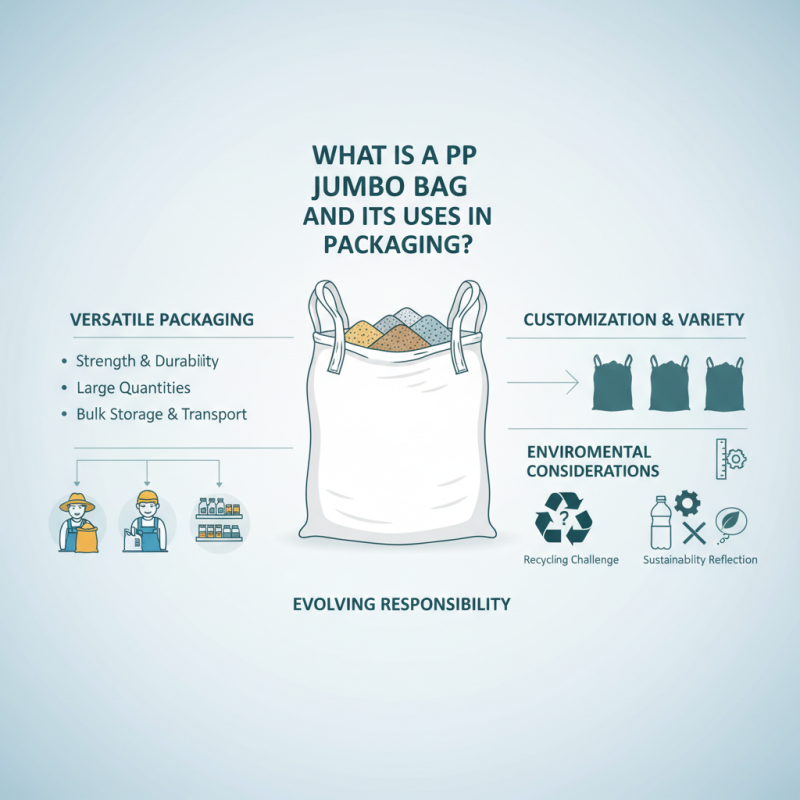

PP jumbo bags are versatile packaging solutions widely used in various industries. These bags, made from polypropylene, offer strength and durability. They are designed to hold large quantities of products, making them ideal for bulk storage and transport. Farmers, manufacturers, and retailers benefit significantly from using PP jumbo bags.

These bags come in various sizes and styles. They can be customized to fit specific needs, enhancing their practicality. One might ponder the environmental impact of using such bags, as they are made from plastic. While they provide convenience, the challenge of recycling them remains a concern.

PP jumbo bags play a crucial role in packaging, yet they evoke reflection on sustainability. Their effectiveness must be weighed against environmental considerations. As industries continue to evolve, the use of these bags must adapt, highlighting the ongoing need for responsible packaging solutions.

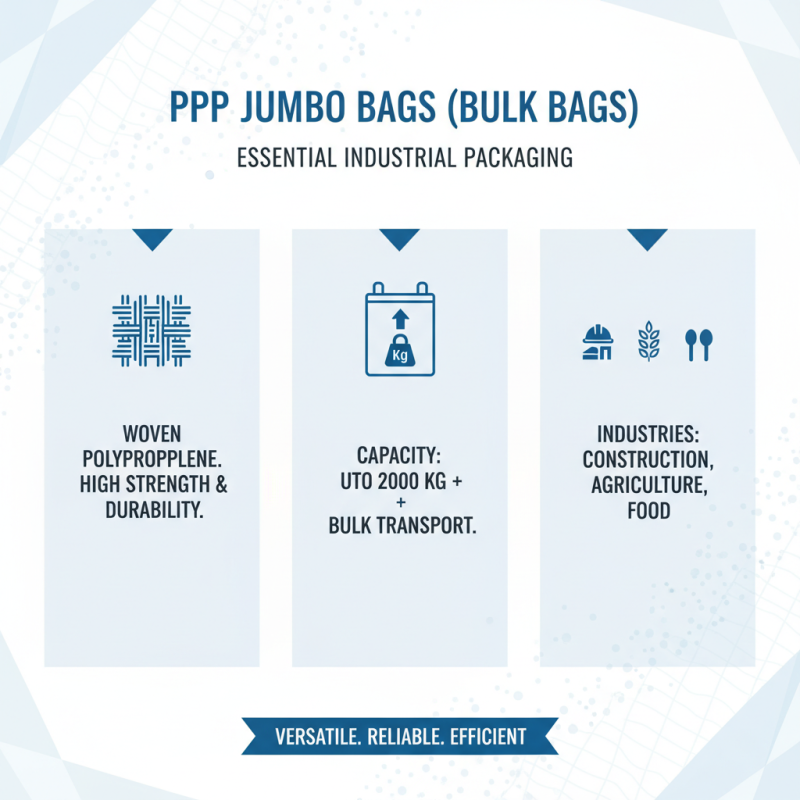

A PP jumbo bag, also known as a big bag or FIBC (Flexible Intermediate Bulk Container), is a large, industrial bag made from woven polypropylene fabric. These bags are designed to hold substantial quantities of materials, often in bulk. They typically come in various sizes, with a standard capacity ranging from 500 kg to 2000 kg. The design features four lifting loops, making it easier to handle with forklifts or cranes.

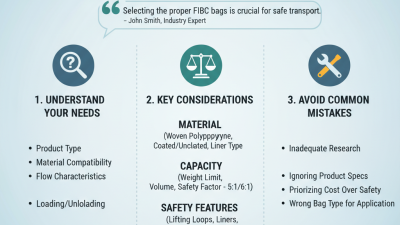

PP jumbo bags are widely used across different industries. They can store grains, fertilizers, minerals, and even construction materials. Their breathable fabric helps maintain the quality of agricultural products. However, it's important to consider the environment when using these bags. While they are reusable, improper disposal can lead to plastic waste.

The production of PP jumbo bags is not without challenges. Ensuring they are sufficiently strong and durable takes careful consideration. Occasionally, defects can occur, leading to failures during transport. Users must reflect on their usage to minimize waste and consider recycling options. This approach can help in reducing the environmental impact as well.

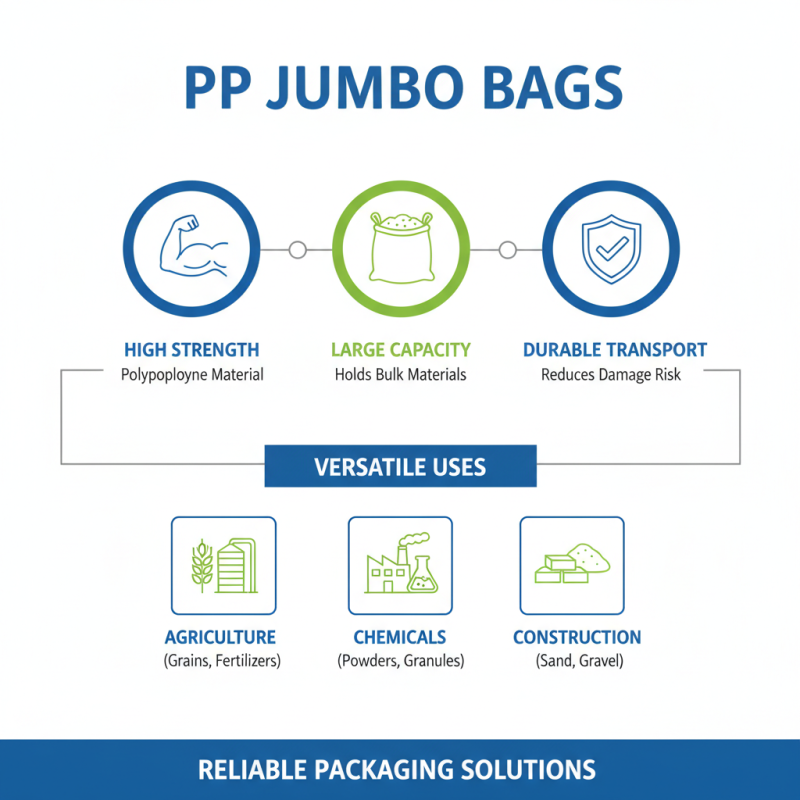

PP Jumbo bags, also known as big bags or bulk bags, are widely recognized in the packaging industry. These bags are designed primarily from polypropylene (PP), a durable and flexible plastic material. This choice of material is crucial for providing strength and resistance to various elements. The bags are typically woven, giving them a robust structure that can hold substantial weight without tearing.

The main advantage of using PP is its lightweight nature combined with high tensile strength. This balance allows for efficient transportation and storage. Additionally, polypropylene is resistant to moisture and many chemicals, making it suitable for different products. Many industries, such as agriculture and construction, utilize these bags for packaging grains, building materials, and even chemicals. However, the production process leaves room for improvement in terms of eco-friendliness.

While PP Jumbo bags serve diverse purposes, there are challenges to consider. Their environmental impact is often a point of reflection. Many users might overlook proper disposal methods, contributing to pollution. Manufacturers are exploring more sustainable solutions. For instance, biodegradable options are emerging, though they still require significant development. Balancing utility with environmental responsibility is essential for future packaging innovations.

PP jumbo bags, also known as bulk bags, are essential in various industries for packaging and transporting materials. These bags are typically made from woven polypropylene, offering high strength and durability. They can hold significant weight, often up to 2,000 kilograms or more. This feature makes them ideal for construction, agriculture, and food industries.

A study by the Flexible Packaging Association indicates that the demand for bulk packaging solutions is increasing significantly. This trend reflects an average growth rate of 4.5% annually. Industries frequently use PP jumbo bags for storing grains, fertilizers, and minerals. Their lightweight nature allows for more efficient shipping. For example, transporting materials in these bags can reduce costs by as much as 15%.

However, challenges exist. Not all PP bags are recyclable, which raises environmental concerns. Some companies may overlook proper disposal methods. Using these bags requires careful management. Ensuring that they are reused correctly can help shift the focus toward sustainability. As industries continue to expand usage, finding a balance between efficiency and environmental responsibility is crucial.

PP Jumbo Bags are versatile and widely used in various industries. One major advantage of these bags is their high strength. Made from polypropylene, they can hold large quantities of materials. This durability reduces the risk of damage during transportation. Whether it's grains, fertilizers, or chemicals, these bags can handle it all.

Another benefit is their cost-effectiveness. Using PP Jumbo Bags often proves cheaper than traditional packaging solutions. They can be reused multiple times, which adds to their value. This saves money in the long run but also raises questions about environmental impact. Reusability is a double-edged sword; while it cuts costs, it could lead to less frequent recycling efforts if not managed properly.

Weight is another factor. PP Jumbo Bags are lightweight compared to alternatives, which makes shipping easier. Yet, this advantage might encourage overpacking, resulting in waste. The balance between efficiency and sustainability remains a challenge. As industries evolve, finding a middle ground becomes essential for future packaging solutions.

PP Jumbo Bags are popular for bulk packaging due to their durability and strength. However, their environmental impact is significant. Many people overlook how these bags affect our planet. The production process of PP Jumbo Bags involves fossil fuels, contributing to carbon emissions. This raises questions about sustainability.

Recycling PP Jumbo Bags can be challenging. While some facilities do accept them, the majority do not. This creates a dilemma for users who want to be environmentally conscious. Often, these bags end up in landfills, where they can last for hundreds of years. This reality is troubling, especially considering their popularity in industries like agriculture and construction.

There is potential for improvement in the industry. Biodegradable alternatives are starting to emerge, but they are not widely adopted yet. People must reflect on their packaging choices. Awareness is key. Choosing sustainable options can lead to better practices in the long run. Each small decision can contribute to a healthier planet. It’s time to rethink packaging, not just for today, but for future generations.

Copyright 2025 © Custom Packaging Products | All Rights Reserved