In the modern logistics and manufacturing landscape, the importance of efficient and reliable packaging solutions cannot be overstated. Flexible Intermediate Bulk Containers (FIBCs) have revolutionized the way bulk materials are stored and transported across various industries. According to a recent report by MarketsandMarkets, the global FIBC market is projected to reach $6.5 billion by 2025, driven by increasing demand for environmentally friendly packaging options and the expansion of industries such as chemicals, food, and agriculture.

Understanding the various types of FIBC bags available is crucial for businesses looking to optimize their supply chain. As industry expert Dr. Alan Thompson points out, "Choosing the right type of FIBC bag not only enhances operational efficiency but also contributes to overall sustainability." These bags are categorized based on their construction, application, and safety features, which means selecting the appropriate type is essential to meeting specific transport and storage requirements.

In this article, we will explore the top 10 types of FIBC bags you need to know for your business, highlighting their unique characteristics and advantages. By arming yourself with this knowledge, you can make informed decisions that will benefit your operation and contribute to the growing trend of sustainable packaging solutions.

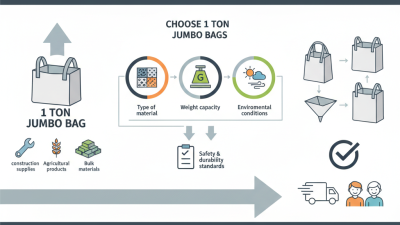

FIBC bags, or flexible intermediate bulk containers, have become indispensable in various industries due to their versatility and capacity for bulk storage and transportation. Understanding the different types of FIBC bags can help businesses choose the right option tailored to specific needs. The primary factors to consider include the bag's design, material, and strength specifications, which cater to a range of applications from agriculture to construction.

There are several common types of FIBC bags, each designed for particular purposes. For instance, the U-panel bag features a simple structure suited for handling powders and granules, while the circular bag offers enhanced strength and stability when transporting aggregates. Additionally, vented FIBC bags are ideal for products that require airflow, such as certain food items or agricultural products.

Meanwhile, conductive FIBC bags are essential for industries dealing with hazardous materials, helping to prevent electrostatic discharge. By selecting the right type of FIBC bag, businesses ensure efficient handling and storage of their products, enhancing both safety and operational effectiveness.

Flexible Intermediate Bulk Containers (FIBC) have become essential in various industries due to their versatility and efficiency in transporting bulk materials. The benefits of using different types of FIBC bags are numerous, and their applications can significantly impact operational productivity. According to a 2022 market report by Grand View Research, the global FIBC market is projected to grow at a CAGR of 5.2% from 2023 to 2030, showcasing the increasing reliance on these bags for efficient logistics and supply chain management.

In industries such as agriculture, construction, and chemical manufacturing, the right type of FIBC bag can enhance safety and reduce costs. For example, anti-static FIBC bags are necessary in environments handling flammable materials, ensuring safety compliance while preventing electrical discharge. Meanwhile, liner FIBC bags provide added protection from moisture and contamination, which is vital for food-grade applications. The use of these specialized bags not only optimizes storage and transport but also minimizes waste, as reported by a study indicating that improper packaging can lead to a 10% increase in material loss during transit.

Moreover, the customization of FIBC bags, including varying sizes and load capacities, allows businesses to meet specific requirements. Research indicates that the ability to tailor FIBC bags can improve material handling efficiency by up to 30%, resulting in lower labor costs and increased staff productivity. Thus, understanding the benefits of each type of FIBC bag can equip businesses with the tools needed to enhance their operations significantly.

When selecting FIBC bags for your business, it is crucial to consider several key features that can significantly impact both performance and efficiency. First and foremost, the type of fabric used in the construction of the bag plays a vital role. Polypropylene is the most commonly used material due to its durability and resistance to environmental factors. The fabric's UV stabilization is another important feature to contemplate, especially if the bags will be exposed to sunlight during storage or transportation.

Another significant consideration is the bag's capacity and dimensions, which should align with your specific product requirements. Ensuring that the bags can hold your materials securely and that they fit within your existing supply chain process can prevent logistical hassles. Additionally, the type of closure—such as drawstrings, fillers, or liners—can affect the ease of filling and discharging the contents. Lastly, the bag's lifting loops should be robust enough to handle the weight of the load while ensuring safety during handling and transport. By focusing on these features, businesses can make informed decisions that enhance their operational efficiency and product safety.

FIBC bags, or flexible intermediate bulk containers, have gained significant popularity due to their versatility and efficiency in transporting various goods. However, their environmental impact and sustainability are critical factors businesses need to consider. Made primarily from woven polypropylene, these bags are lightweight and reusable, which contributes to reducing the overall carbon footprint. Additionally, they can be recycled, allowing businesses to participate in a circular economy that minimizes waste.

When choosing FIBC bags for your business, it’s essential to consider eco-friendly options. Look for suppliers that offer bags made from recycled materials or those that follow sustainable manufacturing practices. This not only helps in reducing environmental impact but can also enhance your brand’s image as a responsible entity committed to sustainability.

**Tips:** When using FIBC bags, ensure they are cleaned and maintained properly to extend their lifespan. Consider implementing a return program for used bags, encouraging recycling and reducing landfill waste. Collaborating with suppliers who prioritize sustainability can also ensure you're making responsible choices for your operations, contributing positively to the environment while fulfilling your business needs.

When it comes to storing and handling FIBC (Flexible Intermediate Bulk Container) bags, following best practices is crucial to ensuring both safety and efficiency in your operations. According to a report by the FIBC Association, improper handling of these bags can lead to costly product loss and increased safety risks, with estimates suggesting that up to 30% of companies experience issues related to inadequate bag storage and handling practices. To mitigate these risks, training personnel on proper techniques for loading, unloading, and storing FIBC bags is essential.

One key best practice is to store FIBC bags in a clean, dry, and well-ventilated area, away from direct sunlight and extreme temperatures. The International Organization for Standardization (ISO) recommends maintaining a storage temperature between 15°C and 25°C to preserve the integrity of the fabric. Additionally, stacking FIBC bags should be done carefully; the maximum stacking height should follow the manufacturer's recommendations, usually not exceeding three to four bags high, to prevent potential collapse and damage to the bags or their contents. Regular inspections for signs of wear and tear, as well as adherence to the manufacturer’s guidelines on handling, can further enhance the longevity and safety of FIBC bags in any business environment.

| Type of FIBC Bag | Material | Max Load Capacity | Applications | Best Practices |

|---|---|---|---|---|

| Standard FIBC | Woven Polypropylene | 1000-2000 kg | Cement, Agriculture | Store in dry conditions. |

| Conductive FIBC | Polyethylene Blend | 1000-1500 kg | Electronics, Chemicals | Avoid static charge by grounding. |

| Ventilated FIBC | Woven Polypropylene | 800-1500 kg | Food Products, Grains | Store away from moisture. |

| Barrier FIBC | Multilayer Material | 1000-2000 kg | Moisture-sensitive Cargo | Seal tightly to prevent air ingress. |

| Open Top FIBC | Woven Polypropylene | 1000-1500 kg | Bulk Material Handling | Use with a cover to prevent contamination. |

| FIBC with Liner | Woven Polypropylene + Liner | 1000-2000 kg | Chemical, Food Products | Inspect liner for damage before use. |

| Baffle FIBC | Woven Polypropylene | 1000-1500 kg | Powders, Granules | Ensure baffles are properly filled. |

| Specialty FIBC | Custom Materials | Varies | Specific Industry Use | Follow manufacturer guidelines. |

| Stackable FIBC | Woven Polypropylene | 1000-2000 kg | Storage & Transport | Stack securely to avoid tipping. |

| Heavy Duty FIBC | High-Density Polypropylene | 2000-3000 kg | Construction Materials, Chemicals | Ensure proper lifting techniques are used. |

Copyright 2025 © Custom Packaging Products | All Rights Reserved