In the world of bulk handling and transportation, ton bags have become an indispensable tool across various industries. According to industry expert John Smith, “The efficiency and versatility of ton bags make them a game-changer in material management.” As businesses strive to optimize their operations, understanding how to effectively buy, store, and use ton bags is crucial. This ultimate guide aims to equip you with essential tips and best practices, ensuring you maximize the benefits of this popular solution.

From construction sites to agricultural settings, ton bags offer a robust and reliable means of transporting and storing bulk materials. However, navigating the options available in the market can be daunting. With various sizes, materials, and specifications, it's important to make informed decisions that align with your specific needs. This guide will explore key considerations to keep in mind when purchasing ton bags, as well as effective storage techniques to maintain their integrity and usability over time. By the end, you will be better positioned to leverage ton bags for your operations, driving efficiency and productivity forward.

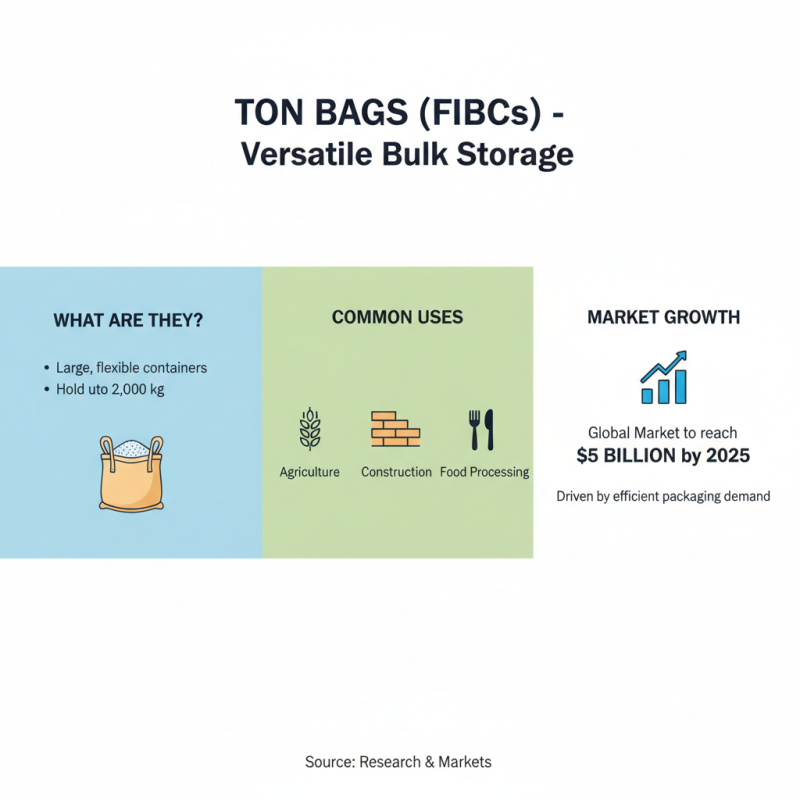

Ton bags, also known as bulk bags or FIBC (Flexible Intermediate Bulk Containers), are versatile storage solutions widely used across various industries, including agriculture, construction, and food processing. Defined as large, flexible bags designed to hold a significant quantity of bulk material, ton bags can safely accommodate weights of up to 2,000 kg, making them ideal for transporting and storing heavy goods. According to a report by Research and Markets, the global market for ton bags is expected to grow substantially, projected to reach USD 5 billion by 2025 due to the increasing demand for efficient packaging solutions.

The applications of ton bags are numerous and varied. In agriculture, they are commonly utilized for storing grains, fertilizers, and seed products, helping to streamline logistics and reduce handling costs. In construction, ton bags are used for sand, gravel, and debris, providing an easy way to manage large volumes of materials on construction sites. Additionally, the food industry employs ton bags for storing grains and other food ingredients, ensuring compliance with health regulations while maintaining product integrity. As industries continue to focus on sustainability and efficient resource management, the ton bag's role in minimizing packaging waste and optimizing storage processes becomes increasingly vital.

When considering the purchase of ton bags, several key factors can influence your decision. First and foremost, material choice plays a crucial role in the durability and functionality of the bag. Look for options made from high-quality woven polypropylene or other strong materials that can withstand the weight and type of materials you intend to carry. Additionally, consider the bag's safety features, such as UV protection and resistance to chemicals if you plan to store sensitive materials.

Another important aspect is the bag's size, as ton bags come in various dimensions to suit different applications. Ensure you select a size that fits your specific needs without compromising structural integrity. Alongside size, evaluate the lifting options available, such as loops or sleeves. This can significantly affect how easily the bag can be handled, loaded, or unloaded.

Tips for buying ton bags include assessing vendor reliability and quality assurance practices. Always seek suppliers with positive reviews and a reputation for quality products. It is also smart to inquire about the bag's load capacity and certifications, as these factors contribute to your overall satisfaction with the product. Finally, when storing ton bags, keep them in a clean, dry environment to prevent deterioration and ensure their longevity for effective use.

When it comes to storing ton bags, safety and efficiency must be prioritized to ensure that the bags maintain their integrity and usability. According to recent industry reports, improper storage can lead to significant product loss, with estimates suggesting that up to 20% of stored materials can be damaged due to inadequate handling practices. Thus, establishing best practices for ton bag storage is essential for maximizing their lifespan and ensuring safety in operations.

One effective approach is to store ton bags in a dry, temperature-controlled environment, away from direct sunlight and moisture, which can weaken the fabric and lead to degradation. Additionally, it is critical to avoid overpacking bags, as this can cause stress on the seams and material, leading to premature wear and potential failure. The Global Bulk Bag Market Analysis highlighted that proper stacking techniques, such as placing lighter bags on top of heavier ones, can prevent crushing incidents and prolong the bags' structural integrity.

Moreover, regular inspections are crucial for maintaining the quality of stored ton bags. A study indicated that proactive monitoring could prevent up to 30% of potential damages through early detection of wear and tear. Employing a first-in-first-out (FIFO) system can also streamline the usage of bags, ensuring that older stock is utilized before newer inventory. By implementing these best practices, businesses can significantly enhance the safety and efficiency of ton bag storage, ultimately leading to cost savings and improved operational performance.

| Dimension | Specification | Best Practices | Storage Tips |

|---|---|---|---|

| Weight Capacity | 1,000 - 3,000 kg | Choose a capacity that fits your project needs | Store in a cool, dry place away from direct sunlight |

| Material | Woven Polypropylene | Opt for UV-resistant options for outdoor use | Avoid stacking extremely heavy bags on top of each other |

| Dimensions | 90 cm x 90 cm x 110 cm | Ensure dimensions align with your transporting methods | Keep bags off the ground to prevent contamination |

| Usage | Construction, Agriculture, Recycling | Use designated bags for specific materials | Label bags for easy identification |

| Lifespan | 1-5 years | Inspect regularly for signs of wear and tear | Rotate stock to use older bags first |

Ton bags, also known as bulk bags or jumbo bags, are versatile tools used across various industries for efficient storage and transportation of materials. In construction, they often hold gravel, sand, or aggregates, allowing for easy transport and organization on-site. In agriculture, ton bags are invaluable for storing fertilizers and animal feeds, helping farmers manage their inventory effectively. Whether you're in construction, agriculture, or food processing, understanding effective methods for using ton bags can greatly enhance operational efficiency.

When utilizing ton bags, it’s essential to choose the right bag type for your specific needs. Look for bags with the appropriate weight tolerance and dimensions that suit your material's size. Additionally, consider the handling requirements; some bags come with lifting straps, which facilitate easier loading and unloading. Properly labeling each ton bag can improve inventory management and reduce the chance of mixing different materials, especially in multi-use environments.

Storing ton bags requires attention to environmental factors. Keep them in a dry area to prevent damage from moisture, which can weaken the bag's integrity. Stacking ton bags should be done carefully, ensuring that they are not overloaded and maintaining balance to prevent accidents. Regularly inspecting your ton bags for any signs of wear or damage can help to avert potential losses before they occur, ensuring that your operations continue smoothly and safely.

When it comes to extending the lifespan of ton bags, proper maintenance is crucial. According to industry reports, ton bags can last between 5 to 10 years when correctly cared for, contributing to sustainability and cost-efficiency for businesses. Regular inspections for signs of wear, such as fraying or discoloration, can help identify issues before they lead to significant failures. Utilizing a maintenance log to track these inspections and any repairs can further enhance the longevity of your ton bags.

Storage conditions play a vital role in the durability of ton bags. They should be kept in a cool, dry place away from direct sunlight and extreme temperatures. Research indicates that exposure to UV rays can shorten the lifespan of these bags by over 30%. Additionally, avoiding overcrowding during storage prevents unnecessary stress on the bags. Implementing rotation practices, where bags in use are swapped with those not in use, can minimize strain on a specific batch and enhance overall utilization efficiency.

Lastly, cleaning ton bags regularly is essential. Guidelines suggest using a mild detergent and water for cleaning, avoiding abrasive materials that might damage the fabric. Proper cleaning reduces the risk of contamination and maintains the integrity of the ton bag. It is advisable to allow bags to air dry completely before storing them to prevent the growth of mold and mildew, further ensuring their longevity and reliability.

Copyright 2025 © Custom Packaging Products | All Rights Reserved