Choosing the right FIBC bags can significantly impact your business. According to industry expert John Smith, “Selecting the proper FIBC bags is crucial for safe transport.” These bags are essential for various industries, from agriculture to construction. However, many overlook their importance.

FIBC bags come in diverse shapes and sizes. Each type serves a specific purpose. Many businesses make the mistake of choosing a bag without understanding their needs. It's essential to consider factors like material, weight capacity, and safety features. A poor choice can lead to product loss or safety hazards.

Reflections on past experiences reveal that many errors stem from inadequate research. Some companies have faced costly setbacks due to improper bag selection. An informed decision can save money and prevent accidents. Understanding the unique requirements of your product is vital in this process.

Understanding FIBC Bags involves exploring different types and their uses in various industries. Flexible Intermediate Bulk Containers (FIBCs) are primarily used for storing and transporting bulk materials. They come in various shapes and sizes. Common types include vented, unvented, and conductive bags. Vented bags allow airflow, which is essential for materials like grains. Unvented bags, on the other hand, are perfect for powders sensitive to air exposure.

When choosing FIBC bags, keep these tips in mind. Assess the material being stored. Is it granular, powdery, or liquid? Each type may require specific bag features. For instance, conductive bags are suitable for hazardous materials. They minimize static electricity. Check the weight capacity. Ensure the bag can handle the load without risk.

Another key aspect is bag design. Some FIBC bags have filling and discharge spouts. These features can enhance efficiency during loading and unloading. Remember to consider how the bags will be used. Will they be stacked or transported frequently? This impacts your choice too. Ultimately, the right selection depends on balancing your needs and the features of the bags available.

When selecting the best FIBC bags, several key factors should be evaluated. The material, typically woven polypropylene, significantly impacts strength and durability. A report from the Flexible Intermediate Bulk Container Association (FIBCA) states that up to 80% of failures in bulk bags arise from poor material choice. Understanding your product’s weight and moisture content helps determine the right bag type.

Another critical factor is the bag size and design. Standard sizes vary, affecting capacity. According to industry data, choosing the wrong size can lead to 20-30% more waste in logistics. Features like loops and closures should match your handling methods. Many users fail to consider how this impacts efficiency and safety during transport.

Compliance with regulations also matters. Ensure the bags meet relevant standards for your application. A study from the International Bulk Port Association highlighted that non-compliant bags lead to significant risks in handling and storage. Not every bag is suitable for all contents, thus careful selection is essential. Investing time in this process ultimately pays off in better performance and reduced costs.

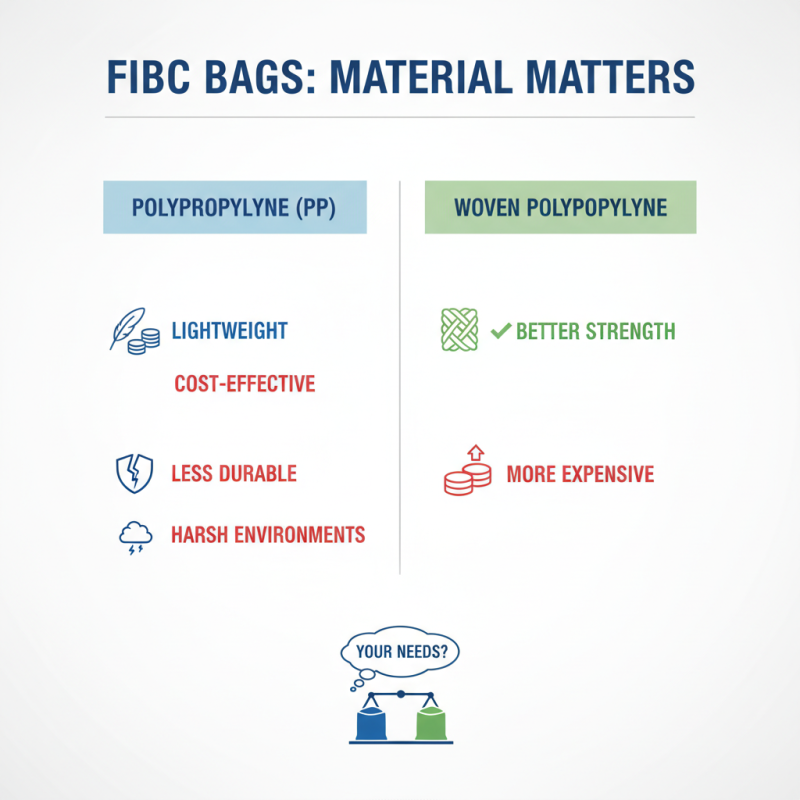

This chart illustrates key factors to consider when selecting FIBC bags, showcasing the importance of different attributes based on user preferences.

When selecting FIBC bags, the material is a key consideration. Polypropylene (PP) is a popular choice. It’s lightweight and cost-effective. However, it may lack durability in harsh environments. On the other hand, woven polypropylene offers better strength but can be more expensive. Think about how these factors apply to your needs.

Another option is conductive FIBC bags. They are ideal for transporting materials sensitive to static. Yet, these bags require careful handling. You need to ensure they meet safety standards. Lastly, laminated bags provide moisture resistance. They are perfect for food products. But, the lamination can increase costs.

When choosing the right bag, keep these tips in mind. Always assess your product's specific needs. Consider weight, fragility, and exposure to elements. Ensure your choice aligns with your budget, but don't sacrifice quality. A cheap bag might lead to more expenses later. Make informed decisions that protect your product and reduce losses.

When selecting FIBC bags, safety and compliance should be the top priorities. According to industry reports, over 30% of FIBC failures are due to improper selection based on the material and environment. Choosing the right bag ensures it meets specific standards, such as ISO 21898 and EN 1000. These standards guarantee the durability and safety of the bags during storage and transport.

Consider the bag’s intended use and environment. For instance, conductive FIBC bags are essential for handling flammable materials. Studies show that using the right type can reduce the risk of ignitions by nearly 75%. Additionally, improperly designed bags can compromise safety. Many companies overlook these details, leading to costly accidents.

It’s vital to assess each bag for compliance with safety regulations. Non-compliance may lead to severe legal penalties. Reports indicate that less than 20% of companies regularly audit their suppliers for adherence to safety standards. Regular assessments can greatly enhance the reliability of FIBC bags, ensuring they perform as expected under pressure. Disregarding these factors could result in overlooked hazards that may negatively impact operations.

| Selection Criteria | Details | Safety Considerations | Compliance Standards |

|---|---|---|---|

| Material Type | Choose between woven polypropylene or other materials based on the application. | Ensure material is resistant to punctures and tears. | Check for compliance with ISO standards. |

| Bag Size | Select the right size based on the volume of material to be transported. | Ensure the bag can handle the weight without risk of failure. | Adhere to local loading and weight regulations. |

| Closure Type | Options include spout top, duffle top, or standard with tie closure. | Consider how easily the bag can be sealed and opened. | Review compliance for secure closure methods. |

| Lifting Options | Evaluate the suitability of lifting loops or sleeves. | Make sure lifting options are durable and reliable. | Follow guidelines for secure lifting in transportation. |

| Static Control | Consider ESD bags if handling sensitive materials. | Prevent electrostatic discharge risks. | Ensure conformance to ESD standards. |

When choosing FIBC bags, cost-effectiveness is crucial. Quality should never be compromised for a lower price. High-quality bags may seem expensive at first glance, but they can save money in the long run. Durable bags reduce the risk of product loss during transportation. This is particularly important for industries dealing with bulk materials.

Consider the materials used to make the bags. Cheaper options might use inferior fabrics that tear easily. Investing in robust materials means fewer replacements and less waste. However, be wary of overly costly options that do not necessarily guarantee better performance.

Evaluate the balance between price and quality. Sometimes, a mid-range bag can meet your needs without breaking the bank. It’s tempting to follow trends or popular choices, which may not suit your specific requirements. Think critically about what you really need. Reflect on past experiences with different suppliers. This can help guide your decision-making process. With careful consideration, you can find the ideal FIBC bags that are both economical and efficient.

Copyright 2025 © Custom Packaging Products | All Rights Reserved